TDCB-Prüfkörper

Zur Navigation springen

Zur Suche springen

The printable version is no longer supported and may have rendering errors. Please update your browser bookmarks and please use the default browser print function instead.

| Ein Service der |

|---|

|

| Polymer Service GmbH Merseburg |

| Tel.: +49 3461 30889-50 E-Mail: info@psm-merseburg.de Web: https://www.psm-merseburg.de |

| Unser Weiterbildungsangebot: https://www.psm-merseburg.de/weiterbildung |

| PSM bei Wikipedia: https://de.wikipedia.org/wiki/Polymer Service Merseburg |

TDCB-Prüfkörper

Die angelsächsische Abkürzung TDCB steht für "Tapered-Double-Cantilever Beam".

Prüfkörperform

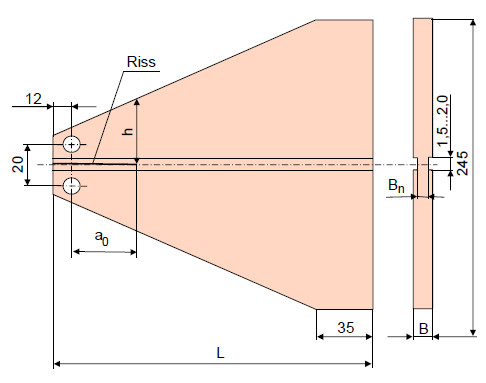

In der Literatur [1–3] finden sich verschiedene Variationen der selben Grundform.

|

|

| Bild 1: | Schematische Darstellung des TDCB-Prüfkörpers |

Ermittlung von bruchmechanischen Kennwerten an TDCB-Prüfkörpern

Bestimmungsgleichung

mit der Belastung durch Zugkraft F und:

Eine umfangreiche Zusammenstellung von geeigneten Prüfkörpern für bruchmechanische Untersuchungen an Kunststoffen und Verbundwerkstoffen ist in Prüfkörper für bruchmechanische Prüfungen enthalten.

Literaturhinweise

| [1] | Blumenauer, H., Pusch, G.: Technische Bruchmechanik. Deutscher Verlag für Grundstoffindustrie, Leipzig Stuttgart (1984) 1. Auflage, S. 109 und S. 146 (ISBN VLN 152-915/61/82; siehe AMK-Büchersammlung unter E 29-1) |

| [2] | Blumenauer, H., Pusch, G.: Technische Bruchmechanik. Deutscher Verlag für Grundstoffindustrie, Leipzig Stuttgart (1987) 2. Auflage, S. 127–129 und S. 140 (ISBN 3-342-00096-1; siehe AMK-Büchersammlung unter E 29-2) |

| [3] | Brown, E. N., Sottos, N. R., White, S. R.: Fracture Testing of a Self-healing Polymer Composite. Experimental Mechanics 42 (2002), No. 4, 372–379 |

| [4] | Kobayashi, T., Broutman, L. J.: Fracture Studies in Rubber-modified Acrylics. 1 Experimental Method: Design of Sandwich-tapered Double-cantilever Beam Cleavage Specimens. Journal of Applied Polymer Science 17 (1973) 1909–1917 |

| [5] | Yaniv, G., Daniel, I. M.: Height-tapered Double Cantilever Beam Specimen for Study of Rate Effects on Fracture Toughness of Composites. In: Whitcomb, J. D. (Eds.): Composite Material: Testing and Design (Eight Conference), ASTM STP 972. ASTM, Philadelphia (1988), S. 241–258 |

| [6] | Hwang, J. H., Kwon, O., Lee, C. S., Hwang, W.: Interlaminar Fracture and Lowvelocity Impact of Carbon/Epoxy Composite Materials. Mechanics of Composite Materials 36 (2000) 117–130 |

| [7] | White, S. R., Sottos, N. R., Geubelle, P. H., Moore, J. S., Kessler, M. R., Sriram, S. R., Brown, E. N., Viswanathan, S.: Autonomic Healing of Polymer Composites. Nature 409 (2001) 794–797 |

| [8] | El-Bagory, T. M., El-Fadaly, M. S., Younan, M. Y. A., Abdel-Latif, L. A.: Influence of Crack Orientation and Crosshead Speed on the Fracture Toughness of PVC Pipe Materials. Journal of Pressure Vessel Technology – Transactions of the ASME 126 (2004) 489–496 |

Normenhinweis

- ISO 25217 (2009-05): Adhesives − Determination of the Mode I Adhesive Fracture Energy of Structural Adhesive Joints using Double Cantilever Beam and Tapered Double Cantilever Beam Specimens

Zusätzliche Literaturhinweise zur Anwendung von TDCB-Prüfkörpern:

Polymere und Polymerverbundwerkstoffe

- Daniel, I. M., Yaniv, G., Auser, J. W.: Rate Effects on Delamination Fracture Toughness of Graphite/Epoxy Composites. Composite Structures 4 (1987) 258–272

- Hwang, J. H., Lee, C. S., Hwang, W.: Effect of Crack Propagation Directions on the Interlaminar Fracture Toughness of Carbon/Epoxy Composite Materials. Applied Composite Materials 8 ( 2001) 411–433

- Gamby, D., Delaumenie, V.: Measurement and Modelling of Crack Propagation Velocity in a Viscoelastic Matrix Composite. Composites Part A – Applied Science and Manufacturing 28 (1997) 875–881

- Li, G. Q., Meng, H., Hu, J. L.: Healable Thermoset Polymer Composite Embedded with Stimuli-responsive Fibres. Journal of the Royal Society Interface 9 (2012) 3279–3287

- Billiet, S., van Camp, W., Hillewaere, X. K. D., Rahier, H., Du Prez, F. E.: Development of Optimized Autonomous Self-healing Systems for Epoxy Materials Based on Maleimide Chemistry. Polymer 53 (2012) 2320–2326

- Jin, H. H., Mangun, C. L., Stradley, D. S., Moore, J. S., Sottos, N. R., White, S. R.: Self-healing Thermoset Using Encapsulated Epoxy-Amine Healing Chemistry. Polymer 53 (2012) 581–587

- Neuser, S., Michaud, V., White, S. R.: Improving Solvent-based Self-healing Materials Through Shape Memory Alloys. Polymer 53 (2012) 370–378

- Coope, T. S., Mayer, U. F. J., Wass, D. F., Trask, R. S., Bond, I. P.: Self-healing of an Epoxy Resin Using Scandium(III) Triflate as a Catalytic Curing Agent. Advanced Functional Materials 21 (2011) 4624–4631

- Brown, E. N.: Use of the Tapered Double-cantilever Beam Geometry for Fracture Toughness Measurements and its Application to the Quantification of Self-healing. Journal of Strain Analysis for Engineering Design 46 (2011) 167–186

- Li, H. Y., Wang, R. G., Liu, W. B.: Toughening Self-healing Epoxy Resin by Addition of Microcapsules. Polymer & Polymer Composites 19 (2011) 223–226

- Mangun, C. L., Mader, A. C., Sottos, N. R., White, S. R.: Self-healing of a High temperature Cured Epoxy Using Poly(dimethylsiloxane) Chemistry. Polymer 51 (2010) 4063–4068

- Brown, E. N., White, S. R., Sottos, N. R.: Fatigue Crack Propagation in Microcapsuletoughened Epoxy. Journal of Materials Science 41 (2006) 6266–6273

- Brown, E. N.: Microcapsule Induced Toughening in a Self-healing Polymer Composite. Journal of Materials Science 39 (2004) 1703–1710

- Kessler, M. R., Sottos, N. R., White, S. R.: Self-healing Structural Composite Materials. Composites Part A – Applied Science and Manufacturing 34 (2003) 743–753

- Meure, S., Wu, D. Y., Furman, S.: Polyethylene-co-methacrylic Acid Healing Agents for Mendable Epoxy Resins. Acta Materialia 57 (2009) 4312–4320

Polymere Adhesive

- Ebewele, R., River, B., Koutsky, J.: Tapered Double Cantilever Beam Fracture Tests of Phenolic-Wood Adhesive Koints. Wood and Fiber Science 11/3 (1979) 197–213

- Ebewele, R. O., River, B. H., Koutsky, J. A.: Tapered Double Cantilever Beam Fracture Tests of Phenolic-Wood Adhesive Joints: Part II. Effects of Surface Roughness, the Nature of Surface Roughness, and Surface Aging on Joint Fracture Energy. Wood and Fiber Science 12/1 (1980) 40–65

- Blackman, B. R. K., Hadavinia, H., Kinloch, A. J., Paraschi, M., Williams, J. G.: The Calculation of Adhesive Fracture Energies in Mode I: Revisiting the Tapered Double Cantilever Beam (TDCB) Test. Engineering Fracture Mechanics 70 (2003) 233–248

- Meiler, M., Roche, A. A., Sautereau, H.: Tapered Double Cantilever Beam Test Used as a Practical Adhesion Test for Metal/Adhesive/Metal Systems. Journal of Adhesion Science and Technology, 13/7 (1999) 773–788

- Davalos, J. F., Madabhusi-Raman, P., Qiao, P. Z., Wolcott; M. P.: Compliance Rate Change of Tapered Double Cantilever Beam Specimen with Hybrid Interface Bonds. Theoretical and Applied Fracture Mechanics 29 (1998) 125–139

- Jin, H. H., Miller, G. M., Pety, S. J., Griffin, A. S., Stradley, D. S., Roach, D., Sottos, N. R., White, S. R.: Fracture Behavior of a Self-healing, Toughened Epoxy Adhesive. International Journal of Adhesion and Adhesives 44 (2013) 157–165

- Cho, J. U., Kinloch, A., Blackman, B., Sanchez, F. S. R., Han, M. S.: High-strain Fracture of Adhesively Bonded Composites Joints in DCB and TDCB Specimens. International Journal of Automotive Technology 13 (2012) 1127–1131

- Marzi, S., Biel, A., Stigh, U.: On Experimental Methods to Investigate the Effect of Layer Thickness on the Fracture Behavior of Adhesively Bonded Joints. International Journal of Adhesion and Adhesives 31 (2011) 840–850

- da Silva, L. F. M., Esteves, V. H. C., Chaves, F. J. P.: Fracture Toughness of a Structural Adhesive Under Mixed Mode Loadings. Materialwissenschaft und Werkstofftechnik 42 (2011) 460–470

- Karac, A., Blackman, B. R. K., Cooper, V., Kinloch, A. J., Sanchez, S. R., Teo, W. S., Ivankovic, A.: Modelling the Fracture Behaviour of Adhesively-bonded Joints as a Function of Test Rate. Engineering Fracture Mechanics 78 (2011) 973–989

- Jin, H., Miller, G. M., Sottos, N. R., White, S. R.: Fracture and Fatigue Response of a Self-healing Epoxy Adhesive. Polymer 52 (2011) 1628–1634

- Wong, C. K. Y., Leung, S. Y. Y., Fan, H. B., Yuen, M. M. F.: Synergistic Toughening of Epoxy-Copper Interface Using a Thiol-based Coupling Layer. Journal of Adhesion Science and Technology 25 (2011) 2081–2099

- Blackman, B. R. K., Kinloch, A. J., Sanchez, F. S. R., Teo, W. S., Williams, J. G.: The Fracture Behaviour of Structural Adhesives Under High Rates of Testing. Engineering Fracture Mechanics 76 (2009) 2868–2889

- Suarez, J. C., Lopez, F., Miguel, S., Pinilla, P., Herreros, M. A.: Determination of the Mixed-mode Fracture Energy of Elastomeric Structural Adhesives: Evaluation of Debonding Buckling in Fibre-Metal Hybrid Laminates. Fatigue & Fracture of Engineering Materials & Structures 32 (2009) 127–140

- Kawashita, L. F., Kinloch, A. J., Moore, D. R., Williams, J. G.: The Influence of Bond Line Thickness and Peel Arm Thickness on Adhesive Fracture Toughness of Rubber Toughened Epoxy-Aluminium Alloy Laminates. International Journal of Adhesion and Adhesives 28 (2008) 199–210

- Kawashita, L. F., Kinloch, A. J., Moore, D. R., Williams, J. G.: A Critical Investigation of the Use of a Mandrel Peel Method for the Determination of Adhesive Fracture Toughness of Metal-Polymer Laminates. Engineering Fracture Mechanics 73 (2006) 2304–2323

- Hadavinia, H., Kawashita, L., Kinloch, A. J., Moore, D. R., Williams, J. G.: A Numerical Analysis of the Elastic-Plastic Peel Test. Engineering Fracture Mechanics 73 (2006) 2324–2335

- Kawashita, L. F., Moore, D. R., Williams, J. G.: Analysis of Peel Arm Curvature for the Determination of Fracture Toughness in Metal-Polymer Laminates. Journal of Materials Science 40 (2005) 4541–4548

- Kawashita, L. F., Moore, D. R., Williams, J. G.: The Measurement of Cohesive and Interfacial Toughness for Bonded Metal Joints with Epoxy Adhesives. Composite Interfaces 12 (2005) 837–852

- Jyoti, A., Gibson, R. F., Newaz, G. M.: Experimental Studies of Mode I Energy Release Rate in Adhesively Bonded Width Tapered Composite DCB Specimens. Composites Science and Technology 65 (2005) 9–18

- Leung, S. Y. Y., Lam, D. C. C., Luo, S. J., Wong, C. P.: The Role of Water in Delamination in Electronic Packages: Degradation of Interfacial Adhesion. Journal of Adhesion Science and Technology 18 (2004) 1103–1121

- Bouchet, J., Roche, A. A., Jacquelin, E.: How do Residual Stresses and Interphase Mechanical Properties Affect Practical Adhesion of Epoxy Diamine/Metallic Substrate Systems? Journal of Adhesion Science and Technology 16 (2002) 1603–1623

- Bouchet, J., Roche, A. A., Jacquelin, E.: The Role of the Polymer/Metal Interphase and its Residual Stresses in the Critical Strain Energy Release Rate (Gc) Determined Using a Three-Point Flexure Test. Journal of Adhesion Science and Technology 15 (2001) 345–369

- Meiller, M., Roche, A. A., Sautereau, H.: Tapered Double Cantilever Beam Test Used as a Practical Adhesion Test for Metal/Adhesive/Metal Systems. Journal of Adhesion Science and Technology 13 (1999) 773–788

- Phipps, M. A., Pritchard, G., Aboutorabi, A.: The Role of Particle Strength and Filler Volume Fraction in the Fracture of Alumina-Trihydrate Filled Epoxy-resins. Polymer & Polymer Composites 3 (1995) 71–77

- Parry, T. V., Wronski, A. S.: A Technique for the Measurement of Adhesive Fracture Energy by the Blister Method. Journal of Adhesion 37 (1992) 251–260

- Brochu, A. B. W., Evans, G. A., Reichert, W. M.: Mechanical and Cytotoxicity Testing of Acrylic Bone Cement Embedded with Microencapsulated 2-Octyl Cyanoacrylate. Journal of Biomedical Materials Research Part B – Applied Biomaterials 102 (2014) 181–189

- Martiny, P., Lani, F., Kinloch, A. J., Pardoen, T.: A Maximum Stress at a Distance Criterion for the Prediction of Crack Propagation in Adhesively-Bonded Joints. Engineering Fracture Mechanics 97 (2013) 105–135

- Marzi, S., Hesebeck, O., Brede, M., Kleiner, F.: A Rate-Dependent Cohesive Zone Model for Adhesively Bonded Joints Loaded in Mode I. Journal of Adhesion Science and Technology 23 (2009) 881–898

- Bland, D. J., Kinloch, A. J., Stolojan, V., Watts, J. F.: Failure Mechanisms in Adhesively Bonded Aluminium: An XPS and PEELS Study. Surface and Interface Analysis 40 (2008) 128–131

- Park, S., Dillard, D. A.: Development of a Simple Mixed-Mode Fracture Test and the Resulting Fracture Energy Envelope for an Adhesive Bond. International Journal of Fracture 148 (2007) 261–271