IRHD hardness

| Ein Service der |

|---|

|

| Polymer Service GmbH Merseburg |

| Tel.: +49 3461 30889-50 E-Mail: info@psm-merseburg.de Web: https://www.psm-merseburg.de |

| Unser Weiterbildungsangebot: https://www.psm-merseburg.de/weiterbildung |

| PSM bei Wikipedia: https://de.wikipedia.org/wiki/Polymer Service Merseburg |

IRHD hardness

General

The IRHD (International Rubber Hardness Degree) hardness test method was developed specifically for elastomers and thermoplastic elastomers, in which the total deformation at small loads is used to obtain characteristic values. The IRHD hardness is determined in accordance with ISO 48-2, which was derived from ISO 48 as part of the renumbering of hardness testing standards. The predecessors of DIN ISO 48 were DIN 53519-1 and DIN 53519-2.

Translated with www.DeepL.com/Translator (free version)

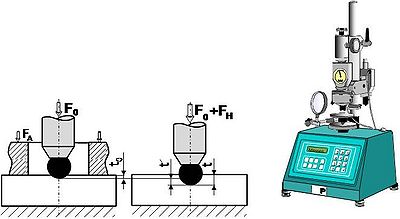

Schematic of the test arrangement

To determine the hardness according to IRHD, a pressure plate is moved without impact until it rests on the test specimen (Fig.). Subsequently, a spherical indenter (ball or pressure rod with spherical tip) is pressed into the test specimen by means of defined forces (contact force and main force). The requirement stated in DIN 53519-1 and -2 that the indenter must be a stainless steel ball is no longer found in subsequent standards.

The indentation depth is indicated on the dial gauge. Due to the design of this test system, it is particularly suitable for determining the hardness of small parts, such as sealing rings or similar.

| Figure: | Test arrangement for determining the IRHD hardness |

Classification of the methods

According to the test standard, the ball indentation hardness IRHD is divided into the methods N (normal test), method H (test at high hardness), method L (test at low hardness) and method M (micro hardness). Essentially, these procedures differ in the diameter of the indentation ball and the load height, whereby these parameters must be selected to suit the respective application. The ball diameters are 2.5 mm for procedure N, 1 mm for procedure H, 5 mm for procedure L and 0.395 mm for procedure M.

The table below shows the different IRHD methods and the corresponding test loads.

| method | Ball diameter (mm) | load (N) | specimen thicknee (mm) | ||

|---|---|---|---|---|---|

| preload | load | total load | |||

| N normal |

2,5 ± 0,01 | 0,3 | 5,4 | 5,7 | 8-10 (>4) 1 to 3 layers |

| H high |

1,0 ± 0,01 | 0,3 | 5,4 | 5,7 | 8-10 (>4) 1 to 3 layers |

| L low |

5,0 ± 0,01 | 0,3 | 5,4 | 5,7 | 8-10 (>4) 1 to 3 layers |

| M micro |

0,395 ± 0,005 | 0,0083 | 0,145 | 0,1533 | 2 ± 0,5 (>1) |

Execution and specification of material values

After the preload has been applied, the test force is applied to a spherical indenter to create a reference plane. This force is 5.4 N for methods N, H and L and 0.145 N for method M. The test load is measured after 30 s under the total test force. The additional indentation depth is measured after 30 s under the total test force applied.

The scale value 0 on the dial gauge corresponds to the maximum indentation and the value 100 to practically no indentation, i.e. very high hardness.

The corresponding International Rubber Hardness Degree (IRHD) can be read off from tables for the indentation depth determined in each case. The hardness scale is chosen so that "0" corresponds to the hardness of a material with YOUNG's modulus zero and "100" to a material with an infinitely large modulus.

References

- Grellmann, W., Seidler, S. (Eds.): Polymer Testing Carl Hanser Munich (2022) 3rd. Edition, pp. 183 (ISBN 978-1-56990-806-8; see AMK-Library under A 22)

- ISO 48-2 (2018-08): Rubber, Vulcanized or Thermoplastic – Determination of Hardness – Part 2: Hardness between 10 IRHD and 100 IRHD

- ISO 48 (2010-09): Rubber, vulcanized or thermoplastic – Determination of hardness (hardness between 10 IRHD and 100 IRHD) (withdrawn)

- DIN 53519-1 (1972-05): Testing of elastomers – Determination of indentation hardness of soft rubber (IRHD); hardness testing on standard specimens (withdrawn)

- DIN 53519-2 (1972-05): Testing of Elastomers – Determination of Indentation Hardness of Soft Rubber (IRHD), Hardness Testing on Specimens of Small Dimensions, Micro-testing (withdrawn)