Bend test

letzte Bearbeitung: 21.08.2023 von: Oluschinski

| Ein Service der |

|---|

|

| Polymer Service GmbH Merseburg |

| Tel.: +49 3461 30889-50 E-Mail: info@psm-merseburg.de Web: https://www.psm-merseburg.de |

| Unser Weiterbildungsangebot: https://www.psm-merseburg.de/weiterbildung |

| PSM bei Wikipedia: https://de.wikipedia.org/wiki/Polymer Service Merseburg |

bend test

General

The quasi-static bend test is used, in particular, for the examination of brittle materials, which cause measurement problems in the tensile test due to their failure behavior. In the case of homogeneous and isotropic plastics, this test is applied according to ISO 178 for testing the following materials [1]:

- thermoplastic injection-molding and extrusion molding compounds, including filled and reinforced molding compounds, as well as rigid thermoplastic sheets,

- thermosetting moulding compounds, including filled and reinforced composites,

- thermosetting sheets, including laminates,

- fiber-reinforced thermosetting and thermoplastic composite materials containing both unidirectional and non-unidirectional reinforcements, and

- thermotropic liquid-crystalline polymers.

However, this test method is not suitable for hard foams or layer composites containing foam. For the determination of the flexural properties of fiber-reinforced plastics, e.g. ISO 14125 [2] is applied to laminates made of GRP or CRP.

In test engineering practice, the three-point and four-point test equipment are available as test arrangements.

The three-point bending test method

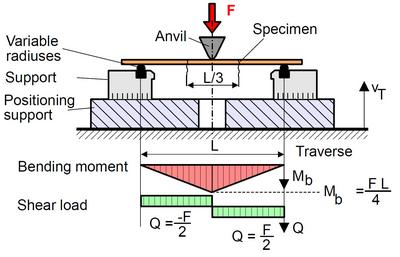

Bending test specimens are used for the experimental investigations. In ISO 178, only the three-point test arrangement is allowed for determining the modulus of elasticity and the flexural properties (Fig. 1).

| Fig. 1: | Three-point bend test equipment according to ISO 178 and ISO 14125 |

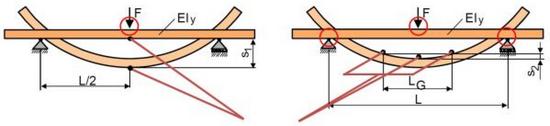

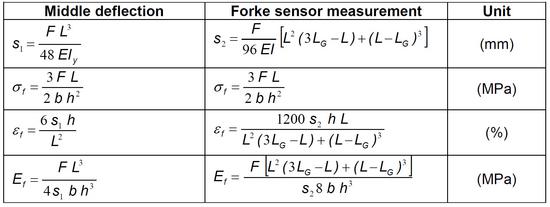

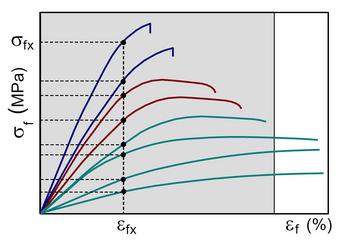

In this standard, measurement of the middle deflection by means of cross-head measurement or the use of a deflectometer in the center of the specimen is permitted. Especially in the determination of the modulus of elasticity, improved characteristic values result for the specimen, since the deflection error is not contained in the deflection signal as a result of the penetration by the deflection anvil. If fork sensors, as shown in Fig. 2, are used, even more precise characteristic values are obtained, since the penetration of the supports is also omitted from the measuring signal. In this case, however, modified evaluation formulas (see table 1) are to be used to calculate the characteristic values of the bending tests. The tests are usually carried out with a support length of 64 mm (h = 4 mm) and test speed of 2 or 5 mm/min until the fracture or maximum load is reached. If no break or maximum occurs, the test is terminated when the conventional deflection of 6 mm (h = 4 mm) is reached. The characteristic values flexural strength and flexural stress at conventional deflection cannot be compared [3]. For comparison with such behavior of plastics, a freely defined yield strength at x % can be used to determine a flexural stress σfx (Fig. 3), although this method is standardized only in the tensile test.

| Fig. 2: | Measurement of middle deflection or deflection using a fork sensor |

| Table 1: | Evaluation formulas for the calculation of the characteristic values of the bend test |

| Fig. 3: | Determination of x %-flexural stress |

The four-point bending test method

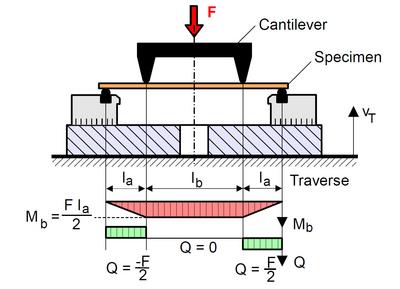

The three- or four-point bending test arrangement can be used on fiber-reinforced plastics according to ISO 14125. The latter testing device (Fig. 4) produces more precise results, but is more expensive and more complicated to handle.

| Fig. 4: | 4P-Bend equipment according to ISO 14125 |

Since this standard does not provide for a break-off criterion as in the case of ISO 178, the tests are usually carried out until the test specimen breaks. Since additional stress components occur as a result of friction or Hertz compression, particularly in the case of large deflections, geometrical effects, such as support shortening, have to be corrected for peripheral fiber strain and flexural stress in the three- and four-point bending device [2].

A comprehensive literature analysis on the mechanical values εf, σfM and σfc for bend loading for numerous plastics is given in [4].

References

| [1] | ISO 178 (2019-04): Plastics – Determination of Flexural Properties |

| [2] | ISO 14125 (1998-03): Fibre-reinforced Plastic Composites – Determination of Flexural Properties, Technical Corrigendum 1 2001-07 |

| [3] | Bierögel, C.: Bend Test on Polymers. In: Grellmann, W., Seidler, S. (Eds.): Polymer Testing. Carl Hanser Verlag, München (2022) 3. Edition, 133–143 (ISBN 978-1-56990-806-8; see under AMK-Library A 22) |

| [4] | Bierögel, C., Grellmann, W.: Bend Loading. In: Grellmann, W., Seidler, S. (Eds.): Mechanical and Thermomechanical Properties of Polymers. Landolt-Börnstein, Volume VIII/6A3, Springer Berlin (2014) 164–191, (ISBN 978-3-642-55165-9; siehe under AMK-Library A 16) |